|

|

|

|

Hydraulic Pressure Booster Turbocharger Energy Recovery Device Series The LPS is the ideal pump for Brackish Water Reverse Osmosis applications, product transfer, and many more applications.

Why use a Turbocharger? - Absolute simplest stand-alone Energy Recovery Device

- Lowest capital and installation costs and lowest maintenance

- Best Life Cycle Cost (LCC) in SWRO systems up to 5,000 m3/day

- Reduces the capital and operating cost of the High Pressure pump and motor

Why choose a FEDCO HPB Turbo?- CFD (Computational Fluid Dynamics) analysis is used to fine tune the HPB to your needs

- Industry-leading three (3) year limited warranty

- Super Duplex SS 2507 is standard MOC

- Custom built to your flow and pressure specifications in 3 to 6 weeks

How FEDCO Turbochargers Work

FEDCO’s Hydraulic Pressure Boosters or HPB energy recovery turbocharger leads the industry in efficiency and reliability. The HPB™ turbocharger reduces the energy consumed in a seawater RO system by up to 50%. With the HPB™, you can recover more than 80% of the wasted high pressure brine energy to reduce the size of the high pressure feed pump, lowering the motor electrical consumption. In the turbocharger, the high pressure concentrate or brine stream from the membranes enters the turbine side of the unit. This high pressure flow spins the turbine impeller of the rotor. The rotor converts the hydraulic energy into mechanical energy used by the pump side impeller. This mechanical energy provides a pressure boost to the feed stream. This boost reduces the pressure requirement of the RO system high pressure feed pump. The one piece custom engineered rotor feature the patented RotorFlo™ technology that eliminates external lubrication lines ensuring maximum reliability and minimal maintenance.

Standard HPB Series

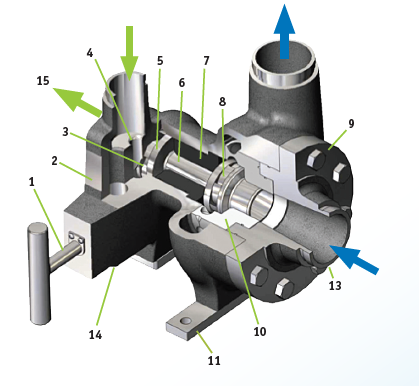

(HPB-10, HPB-20, HPB-30, HPB-40, HPB-60, HPB-90, HPB-130, HPB-180, HPB-250, HPB-350)

With ten (10) models, there is a perfect fit for your most demanding performance, reliability and project schedule requirements. Standard MOC is Duplex SS 2205, however, Super Duplex SS 2507 is optional. Brine nozzle valve actuators, flanged connections and other options are available. Delivery of the standard line HPBs are built to your flows and pressures specifications in three (3) to (6) weeks in Duplex SS 2205.

- Variable area in nozzle (needle type for precise control)

- Nameplate

- Thrust bearing – patent pending design, allows dry running

- Brine nozzle and volute

- Brine (turbine) impeller

- Rotor shaft

- Center bearing — lubricated by feed, ZERO brine leakage to feed

- Feed (pump) impeller

- End cap

- Multi-vane diffuser — radial pressure balanced for long wear ring and bearing

- Mounting foot (varies by model)

- O-rings — all bearings mounted on o-rings for easy removal

- Victaulic-type pipe joints (flanged joint optional)

- Standard Duplex SS 2205 MOC (Super Duplex SS 2507 optional)

- Can discharge brine at higher pressure for easy brine disposal

Mega System HPB

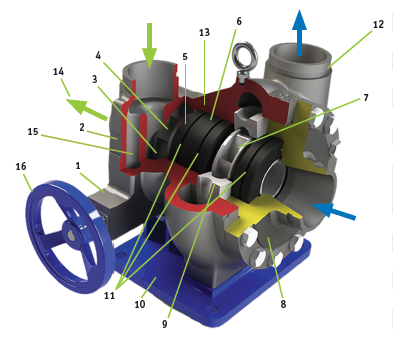

(HPB-500, HPB-700, HPB-1000, HPB-1400, HPB-2000, HPB-2800)

Six (6) models cover the largest current and anticipated SWRO trains. Standard MOC is Duplex SS 2205 with Super Duplex SS 2507 optional. Brine nozzle valve actuators, flanged connections and other options available.

- Brine aux nozzle valve (needle type for precise control)

- Nameplate

- Thrust bearing — patent pending design, allows dry running

- Brine (turbine) impeller

- Rotor shaft — integral with impellers (hidden in this view)

- Center bearing — lubricated by feed, ZERO brine leakage to feed

- Feed (pump) impeller

- End cap

- Multi-vane diffuser —radial pressure balanced for long wear ring and bearing life, provides higher efficiency than volutes

- Baseplate

- O-rings — all bearings mounted on o-rings for easy removal

- Victaulic-type pipe joints (flanged joints optional)

- Standard Duplex SS 2205 MOC (Super Duplex SS 2507 optional)

- Brine can be discharged at higher pressure for easy brine disposal

- Integral brine passage for auxiliary turbine nozzle

- Hand wheel, optional valve actuator, for brine flow regulation

HPB-130 OPERATING PARAMETERS | Liquid | Seawater, brackish water, and fresh water | | Operating Temperature | 0.6 - 70.0°C | | Maximum Storage Temperature | 85°C | | Minimum Pump-Side Flow | 60 m3/h | | Maximum Pump-Side Flow* | 156 m3/h | | Maximum Operating Pressure | 83 bar | | Minimum Brine Outlet Pressure | Varies upon design | | Nominal Sound | 75-85 dBA | | Nominal Vibration | 0.05"/sec - 0.15"/sec | | Filtration Requirement | 20 microns |

*Range may vary.

HPB-130 OPERATING PARAMETERS| Liquid | Seawater, brackish water, and fresh water | | Operating Temperature | 0.6 - 70.0°C | | Maximum Storage Temperature | 85°C | | Minimum Pump-Side Flow | 60 m3/h | | Maximum Pump-Side Flow* | 156 m3/h | | Maximum Operating Pressure | 83 bar | | Minimum Brine Outlet Pressure | Varies upon design | | Nominal Sound | 75-85 dBA | | Nominal Vibration | 0.05"/sec - 0.15"/sec | | Filtration Requirement | 20 microns |

*Range may vary.

|

|

|

|

|

|

|